StarMix

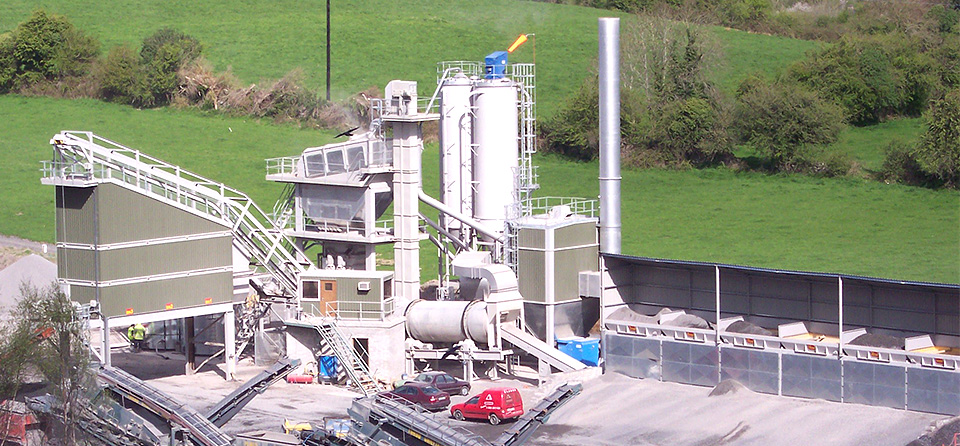

Static Asphalt Plants

Starmix models are available from 160 TPH to 400 TPH with high-level and environmental options.

- Flexibility of plant layout - standard or high level design

- Low maintenance operation

- Optional Environmental design - sheeted and clad to customers requirements

- High thermal efficiency dryer with unique replaceable lifter design

- Multi-fuel burner

- Fully automatic controls

- Can be extended/retrofitted with numerous options at a later stage

The StarMix range embodies all that is the very best in asphalt plant design.

A first choice for contractors making a major long term investment in a high capacity, high performance plant and seeking to secure and ensure reliable, financially viable, quality asphalt production and supply on a regional basis for many years to come.

Meeting all the criteria for a high performance and environmental plant, the StarMix is able to provide major asphalt production capabilities and can draw on an extensive range of options and configurations to choose from.

Specific and exacting requirements of individual clients are able to be met in full in this high-end market sector.

Features

Multi-hopper Cold Feed

Compact transportable multi-hopper, cold feedunit with built in collecting conveyor and dryerfeed conveyor. Direct drive geared motor unitsgive high reliability. Accurate variable speedcontrol via AC motor and inverter.

High thermal efficiency Dryer

Fully insulated and clad aggregate dryer.Drive by electric motors and gear unit throughpolymer friction drive support rollers.

Fully enclosed Screen

Twin shaft oil lubricated screen fully enclosedin an accoustic dust housing.

Twin shaft Paddle Mixer

Fully synchronised twin shaft paddle mixer with abrasion resistant liner plates, paddle arms and tips.

High Level Option

The high level configuration incorporates mixed material storage silos directly beneath the paddle mixer.

Sheeted Option

Sheeting contains dust and reduces noise levels in sensitive locations.

Options

- Thermal insulation on the aggregate dryer drum

- Environmental sheeting options

- High level option to incorporate mixed material storage

- Heavy oil, gas or multi-fuel burners

- RAP and fibre additive systems

Specifications

| Units | SM2000 | SM3000 | SM4000 | SM5000 | |

| Plant Capacity | |||||

| Output* | tph | 160 | 240 | 320 | 400 |

| Cold Feed | |||||

| Hopper Capacity (heaped) | m³ | 9.5 | 11.5 | 15.0 | 15.0 |

| Hopper Loading Width | m | 3.0 | 3.5 | 4.0 | 4.0 |

| Belt Feeder Length | m | 1.5 | 1.8 | 1.8 | 1.8 |

| Belt Width | mm | 500 | 600 | 750 | 900 |

| Belt Feeder Drive | kW | 2.2 | 3.0 | 3.0 | 4.0 |

| Vibrator Fitted to Sand Hopper | YES | YES | YES | YES | |

| Collecting Conveyor Width | mm | 600 | 750 | 800 | 900 |

| Collecting Conveyor Drive | kW | 5.5 | 5.5 | 7.5 | 7.5 |

| Aggregate Dryer | |||||

| Dryer Drum Diameter | m | 2.2 | 2.5 | 2.8 | 3.1 |

| Dryer Drum Length | m | 8.0 | 9.0 | 10.0 | 11.0 |

| Dryer Drive | kW | 4 x 15.0 | 4 x 22.0 | 4 x 30.0 | 4 x 37.0 |

| Dryer Capacity | tph | 180 | 260 | 340 | 420 |

| Air Volume | |||||

| Dryer | m³/h | 62,600 | 80,835 | 101,400 | 124,230 |

| Mixing Section | m³/h | 9,990 | 12,623 | 17,425 | 21,425 |

| Total | m³/h | 72,590 | 93,458 | 118,825 | 145,655 |

| Hot Stone Elevator, Screen & Mixing Section | |||||

| Elevator Capacity | tph | 180 | 260 | 340 | 420 |

| Elevator Drive | kW | 22.0 | 30.0 | 30.0 | 45.0 |

| Screen Decks | No. | 6 (6 sizes + rejects) | 6 (6 sizes + rejects) | 6 (6 sizes + rejects) | 6 (6 sizes + rejects) |

| Screen Length | m | 3.3 | 4.0 | 4.0 | 5.0 |

| Screen Width | m | 1.8 | 2.2 | 2.2 | 2.6 |

| Screen Drive | kW | 2 x 15 | 2 x 15 | 2 x 15 | 2 x 22 |

| Hot Storage Capacity | t | 60 | 60 | 60 | 60 |

| Hot Storage Bins | No. | 6 | 6 | 6 | 6 |

| Aggregate Weigh Hopper Capacity | kg | 2250 | 3250 | 4250 | 5250 |

| Bitumen Weigh Hopper Capacity | kg | 350 | 550 | 650 | 800 |

| Filler Weigh Hopper Capacity | kg | 450 | 650 | 900 | 1050 |

| Paddle Mixer Capacity | kg | 2250 | 3250 | 4250 | 5250 |

| Paddle Mixer Drive | kW | 2 x 22.0 | 2 x 37.0 | 2 x 45.0 | 2 x 55.0 |

English (UK)

English (UK)  Русский (RU)

Русский (RU)