���������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������

High performance machines suitable for use in secondary or tertiary applications where reliability coupled with versatile mobility is required.

Featuring the GC cone crusher for maximising production; they are renowned for achieving significant rates of reduction, cubical product shape and providing high quality aggregate and sub-base material. The GC series can also be fitted with a recirculating conveyor and single deck screen to further reduce oversize material in a complete pass.

- Robust and durable crushers featuring rapid setup times

- High throughput capacity and large reduction rates

- Hydraulically adjustable crusher settings

- Advanced electronic control system interface

- Easily accessible maintenance and service points

- Simple hydraulic circuits

- Efficient CATERPILLAR® powerpack designed for low operating cost

- Global aftersales service, support and spare parts supply

GC1000

|

Jaw Feed Opening |

700mm x 45mm (28" x 18") |

| Max Feed Size |

410mm |

| Setting Range |

40-125mm with hydraulic cylinders (1.5"-5") |

| Capacity |

upto 130 t/h (145 ton/h) |

GC1200

|

Jaw Feed Opening |

900mm x 600mm (35" x 24") |

| Max Feed Size |

560mm (22") Cubed |

| Setting Range |

50-200mm (2"-8") |

| Capacity |

upto 330 t/h (363 ton/h) |

GC1450

|

Jaw Feed Opening |

1100mm x 650mm (43" x 26") |

| Max Feed Size |

625mm (cubed) |

| Setting Range |

65-175mm with hydraulic cylinders (2.5"-7") |

| Capacity |

upto 350 t/h (385 ton/h) |

-

CONE

Variable belt speed for a controlled continuous feed, monitored by a flow sensor and a metal detector.

-

Belt Feeder

Variable belt speed for a controlled continuous feed, monitored by a flow sensor and a metal detector.

-

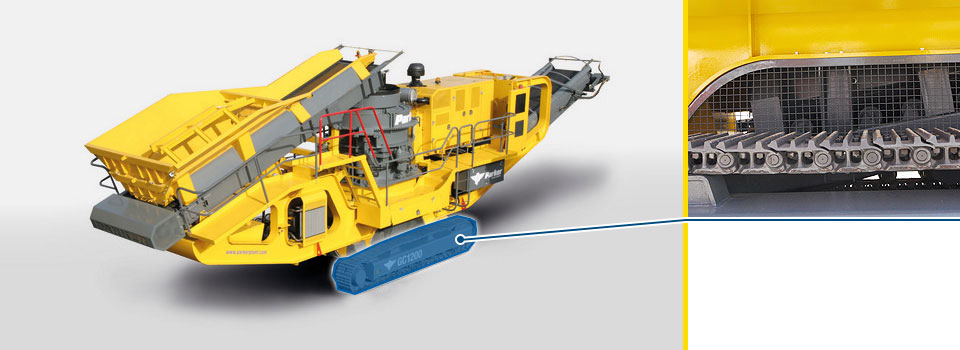

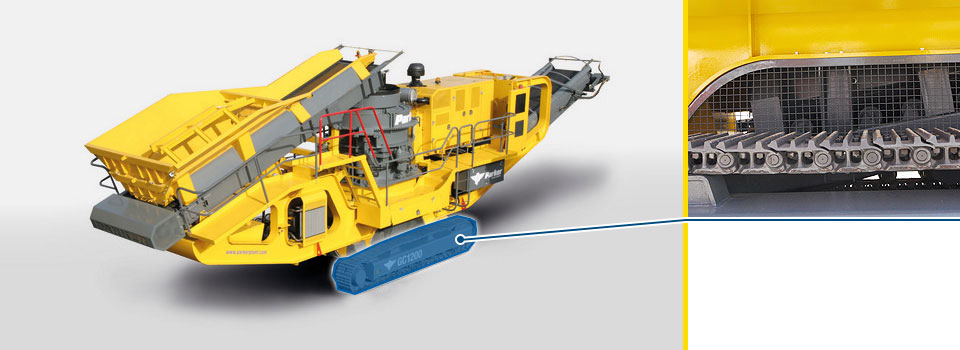

Track Frame

Heavy duty tracks suitable for any environment.

-

Hydraulic Oil Coolers

Two hydraulic oil coolers fitted as standard for maximum productivity in warmer climates.

-

Feed Hopper

Manufactured from wear resistant steel with impact diverter bars to protect the heavy duty feeder belt.

-

Lubrication Cooler

Efficient lubrication cooler to ensure reliable operation.

-

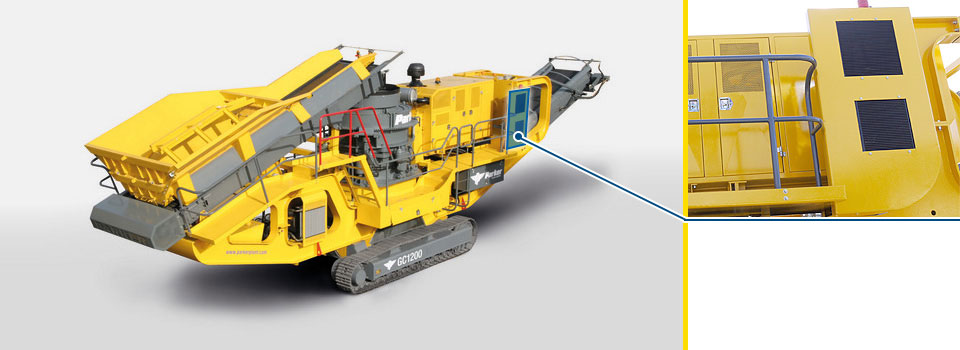

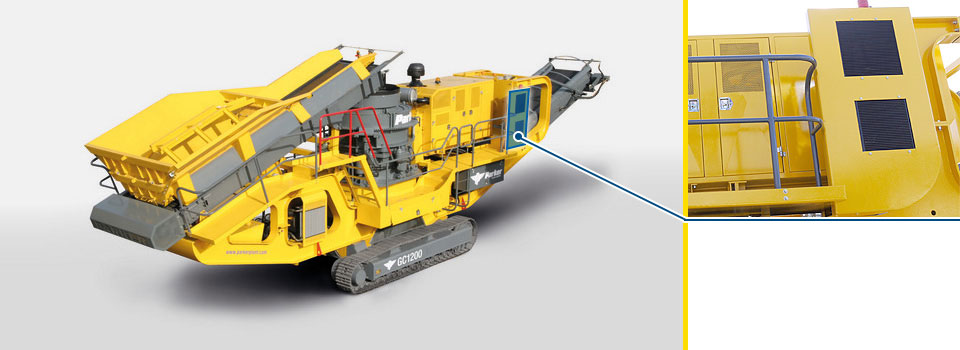

Access & walkways

Access platforms to hydraulic tank, engine, cone crusher, and feed hopper.

-

Dust Suppression System

Water spray system fitted to the forward product conveyor.

-

Forward Product Conveyor

Extra wide product conveyor with full length rubber side skirts utilising wear resistant steel clamp plates. Maximised discharge height for product stockpiling. Optional screen and recirculating conveyor can be provided.

-

Powerpack

CATERPILLAR® engine as standard, compliant to industry regulations.

-

Extra Heavy Duty Chassis

Designed and engineered web and flange chassis, fully welded and fabricated from high grade steel to withstand the rigors of operation and transportation.

English (UK)

English (UK)  Русский (RU)

Русский (RU)