���������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������

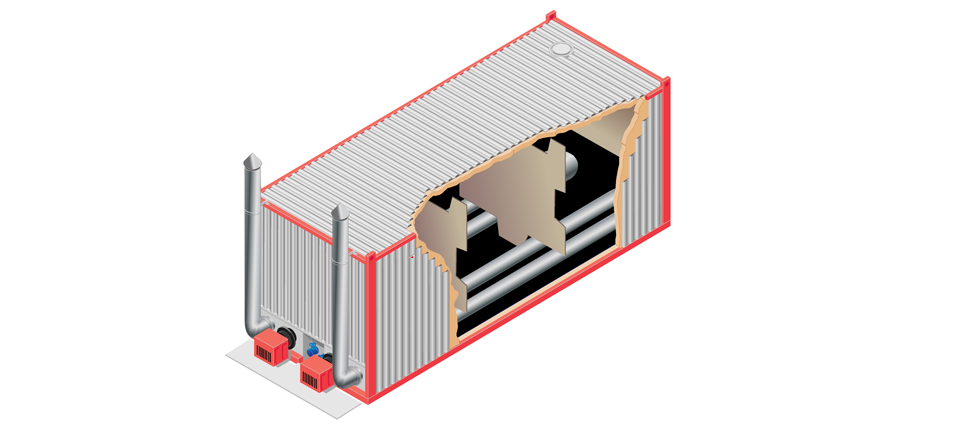

The Parker ISO 20 Bitumen Container is designed to provide the ideal multi-modal solution for the transportation of bitumen world-wide.

Constructed as a standard 20 foot ISO tank container with Lloyd's approval it is suitable for transportation by sea, road and rail and allows a number of containers to be set up to provide a temporary or semi-permanent tank farm on site.

We offer a full installation package to suit individual needs including light fuel oil burners, pumps and pipe work.

- High degree of fabrication integrity

- Payload capacity of 29,000 litres

- Lloyd's approval for shipping as a tank container

- Direct oil fired heating system

- Twin heating tubes to permit rapid elevation of product temperature

- Rigid foam insulation and robust external finish

- Optional stainless steel flame tube liners to prevent localised hot spots

- Optional fully automatic pressure jet burners

- Easy to operate & require minimal maintenance

- Rapid on site set up times

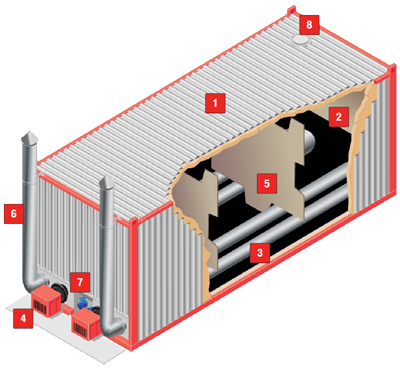

Key

- ISO Container - Outer Tank

- Inner Tank - 29,000L Capacity

- ‘U’ Shaped Flame tubes

- Quick Fit Fully Automatic Burners

- Internal Surge Protection Plates

- Quick Fit Exhaust Flues

- Drain/Discharge Valves Points

- Fill Point Connection

Outer Tank

- Standard 20 foot ISO container

- ISO 1496 part 3 – type 75 container

- Lloyds approved

- One 200mm inlet spigot on the roof to allow quick filling

Heating Method

- Stainless steel liners to prevent localised hotspots

- 240V fully automatic oil burners

- ‘Easifit’ electrical connections with ‘DIN’ plug and socket connections

- Skid mounted transportable fuel tank with flexible connections to burners

Transfer Discharge Pump

- Rotary gear type skid mounted pump

- Electrically heated

- Capacity of 21,000 litres per hour

- Driven by 7.5 kW direct coupled electric motor

Inner Tank

- Rectangular section fabricated from 4mm plate

- Baffle plates fitted to prevent liquid surge

- 75mm of rigid foam insulation fitted

- Two “U” shaped flame tubes to permit rapid heating

- Two flanged burner mountings

- Two flanged exhaust stack mountings

Control Panel

- Lockable IP55 cabinet with weather canopy

- Plug and socket connections for incoming power and burner supply

- Individual burners controlled from the panel

- Thermostatic temperature control of product

Flexible Hose Assemblies

- Braided steel bitumen hoses

- Canvas covered

- For connection from container to pump and to other equipment

English (UK)

English (UK)  Русский (RU)

Русский (RU)