Cone Crushers

Standalone, Tracked, Wheeled & Static Cones

Parker Plant offers two types of cone crushers: the standard speed bronze bushing design & the high-speed bronze bushing design (GC Series).

The Standard Cone incorporates modern user-friendly features such as hydraulic tramp relief & fully hydraulic crusher adjustment. GC Series cones have compact designs that run at higher speeds to provide additional reduction capacity & performance.

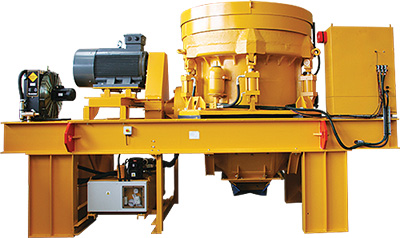

Cone Crusher Base Units

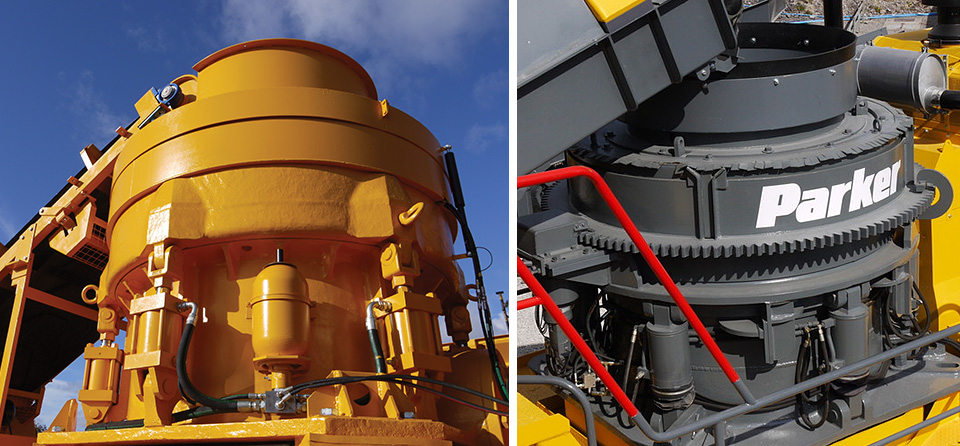

Standard Cone Crusher

Designed to operate across a wide range of duties, the Parker cone can be fitted with any one of seven different cavity profiles from extra coarse through to extra fine, giving this machine outstanding versatility.

The cone features all hydraulic setting adjustment under load with independent hydraulic tramp metal relief assuring a high degree of protection from damage to the crusher.

Using both hydraulic systems to raise the bowl, a blocked crusher can be cleared almost immediately, reducing downtime and increasing productivity. This feature is especially useful when working on demolition projects where irregular or uncontrolled feeds are likely.

- Push button hydraulic setting adjustment

- Automatic hydraulic overload/tramp iron protection system

- Cavity clearing - double the clearance lift of most other cone crushers

- Totally unrestricted feed opening

- Compact crusher design - suited to mobile plants or height restricted installations

- Fully automatic oil lube system

- Choice of seven standard cavity configurations

| Size | Cavity | Recommended Minimum Discharge Setting (mm) |

Feed Opening (mm) | Crusher Closed Side Setting (mm) Recommended Range | Maximum Jaw Setting (mm) | |||||||||||

| Open Side | Closed Side | 6 | 8 | 10 | 12 | 15 | 20 | 25 | 30 | 35 | 40 | 50 | ||||

| 900 | Extra Fine | 6 | 45 | 30 | 55 | 65 | 70 | 80 | ||||||||

| Fine | 8 | 65 | 45 | 70 | 80 | 85 | 95 | |||||||||

| Medium Fine | 10 | 85 | 65 | 80 | 90 | 100 | 115 | |||||||||

| Medium | 12 | 115 | 95 | 95 | 105 | 120 | 135 | 150 | 65 | |||||||

| Medium Coarse | 15 | 150 | 130 | 110 | 125 | 140 | 165 | 190 | 75 | |||||||

| Coarse | 25 | 180 | 165 | 150 | 170 | 195 | 220 | 115 | ||||||||

| Extra Coarse | 30 | 215 | 200 | 180 | 210 | 235 | 125 | |||||||||

| 1200 | Extra Fine | 6 | 75 | 55 | 85 | 95 | 100 | 110 | ||||||||

| Fine | 8 | 90 | 65 | 100 | 105 | 120 | 130 | |||||||||

| Medium Fine | 12 | 115 | 90 | 130 | 145 | 165 | 180 | |||||||||

| Medium | 15 | 145 | 135 | 150 | 170 | 195 | 225 | 115 | ||||||||

| Medium Coarse | 20 | 170 | 155 | 175 | 205 | 230 | 265 | 300 | 125 | |||||||

| Coarse | 25 | 210 | 195 | 210 | 240 | 275 | 315 | 350 | 140 | |||||||

| Extra Coarse | 30 | 250 | 230 | 255 | 290 | 340 | 380 | 150 | ||||||||

| 1350 | Extra Fine | 6 | 75 | 55 | 120 | 130 | 145 | 160 | ||||||||

| Fine | 10 | 100 | 75 | 150 | 170 | 190 | 200 | |||||||||

| Medium Fine | 15 | 125 | 95 | 200 | 220 | 235 | 250 | |||||||||

| Medium | 20 | 160 | 145 | 225 | 245 | 290 | 320 | 125 | ||||||||

| Medium Coarse | 25 | 210 | 190 | 260 | 300 | 340 | 380 | 150 | ||||||||

| Coarse | 30 | 250 | 230 | 330 | 370 | 415 | 455 | 180 | ||||||||

| Extra Coarse | 35 | 280 | 260 | 400 | 445 | 490 | 200 | |||||||||

Global Cone Crushers

The GC series of cone crushers feature a highly rugged, more compact design than the standard cone.

While generally operating at higher speeds, the GC cone features several eccentric throw and speed combinations to maximise performance and give greater reduction capability as well as higher application throughputs.

The hydraulically adjusted and clamped screw top design provides accurate and consistent control and regulation of crusher setting.

- Higher rotation speed and higher eccentric height for bigger crushing ratio.

- Mantle and concave for coarse, medium and fine crushing can be installed in the same top cell assembly.

- Higher rotation speed up to 800 RPM to obtain higher capacity.

- Increased height of concave for improved crushing efficiency.

- Automatic over-load protection.

- Equipped with advanced hydraulic control system for simple operation and less manpower.

- Strong main frame with high power transmission rate for longer service life of the drive device.

GlobalCone Range |

||||||||||

| Model No. | Maximum Feed Size (mm) |

Minimum Discharge Opening (mm) | Motor Rating (Kw) | Throughput Tons/Hour (TPH) | Weight (Kg) | |||||

| Closed Side Discharge Opening (mm) | ||||||||||

| 19mm | 22mm | 25mm | 38mm | 45mm | 51mm | |||||

| GC-C200 | 185 | 19 | 110-150 | 165-185 | 180-210 | 200-240 | 265-310 | 12000 | ||

| GC-F200 | 145 | 17 | 110-150 | 145-165 | 160-195 | 185-220 | 230-280 | 12000 | ||

| GC-C300 | 210 | 22 | 180-225 | 210-240 | 230-280 | 290-350 | 320-380 | 360-430 | 18700 | |

| GC-F300 | 185 | 19 | 180-225 | 190-220 | 205-230 | 225-260 | 270-330 | 18700 | ||

| GC-C400 | 290 | 25 | 220-300 | 295-355 | 370-480 | 430-500 | 470-550 | 28400 | ||

| GC-F400 | 210 | 22 | 220-300 | 265-310 | 290-330 | 350-410 | 390-440 | 28400 | ||

Static Cone Crushers

ConeRanger CP

The Parker ConeRanger CP is a stationary crushing plant designed to operate in a secondary or tertiary role.

The transportable chassis offers easy movement between locations and rapid on-site set up.

Incorporating the well proven fully hydraulic Parker Cone Crusher, this unit is ideal for working in a composite crushing arrangement with Parker primary crushing plants, screens and conveyors.

- Full mobile or transportable options

- Fast on-site set up

- All models travel easily

- Rugged practical design

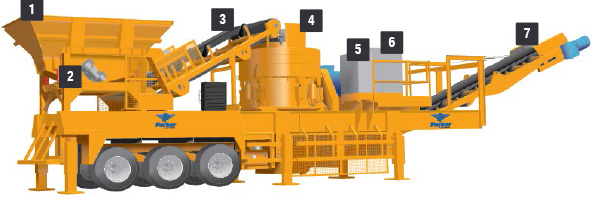

Mobile Cone Crushers

Our range of CE and CA configurations allow the customer more flexibility when it comes to mobile / wheeled equipment.

ConeRanger CE

The CE is a high-capacity, extremely mobile secondary crushing unit suitable for demolition, quarry or gravel feed application.

Built around a strong straight beam chassis with standard supports for feed section, crusher, power unit and conveyor frame.

The chassis is complete with access/maintenance platforms to the crusher and power unit and a main operators platform overlooks all stages of operation.

- Rugged practical design incorporating the well proven fully hydraulic Parker Cone Crusher

- Powered electrically and hydraulically by a self contained diesel engine power pack

- Quick on-site installation promoted by the hydraulic front jacking and product conveyor folding facilities

-

Feed Hopper

Large capacity steel plate feed hopper with external reinforcement, and with nominal feed mouth

-

Vibrating Feeder

Vibratray feeder with variable speed drive from twin contra-rotating hydraulic/electric motors

-

Feed Conveyor

Troughed belt conveyor, driven by hydraulic motor or electric drive, which fold back manually for maintenance access to the cone cavity

-

Cone Crusher & Hydraulic Control System

Parker 900, 1200 or 1350 cone fitted with any one of seven interchangeable crushing cavities.

-

Power Unit

Either Electric or diesel hydraulic Caterpillar engine or similar if stated otherwise

-

Control Functions

Setting adjustment, even under full crushing load. Hydraulic overload tramp iron protection.

-

Product Conveyor

Wide troughed belt conveyor with heavy duty three-roller impact idlers under crusher discharge.

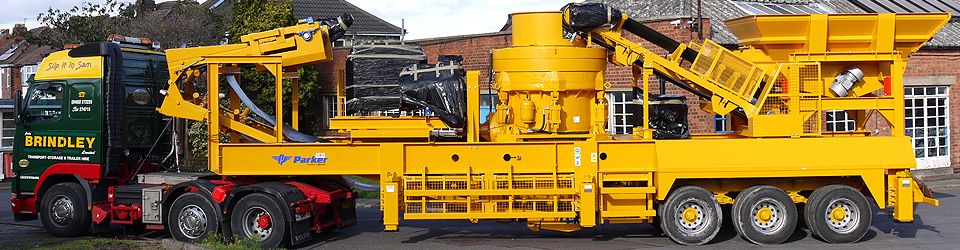

ConeRanger CA

The ConeRanger CA is a fully mobile crushing unit designed to operate in a secondary or tertiary role.

The mobile chassis offers easy transportation between locations and rapid on-site set up. Incorporating the well proven fully hydraulic Parker Cone Crusher, this unit is ideal for working in a composite crushing arrangement with Parker primary crushing plants, screens and conveyors.

English (UK)

English (UK)  Русский (RU)

Русский (RU)