���������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������

Containerised Concrete Plants

With a production capacity of 30m³/h the ConStar 750C meets all the requirements for small to medium sized projects where there is a need for ready-mix or pre-cast concrete produced to the highest quality standards.

The unique skip weighing system and folding design of the ConStar 750C eliminates the need for a weigh conveyor and allows the main structure to be transported inside a single 12m (40ft) open top container.

Controls on the ConStar 750C are easy to use, designed to ensure high levels of accuracy, batch repeatability and mix consistency which are vital for the production of high quality, high strength concrete.

-

Cement Weigh Hopper

Mounted above the pan mixer; the cement weigh hopper features a 300kg capacity hopper mounted on three load cells for accurate weighing. Delivery into the pan mixer is controlled by a pneumatically operated butterfly fly valve.

-

Water Weigh Hopper

The 250kg capacity water hopper suspended on load cells is supplied by a 2 stage water delivery system and mounted above the mixer to ensure higher accuracy.

-

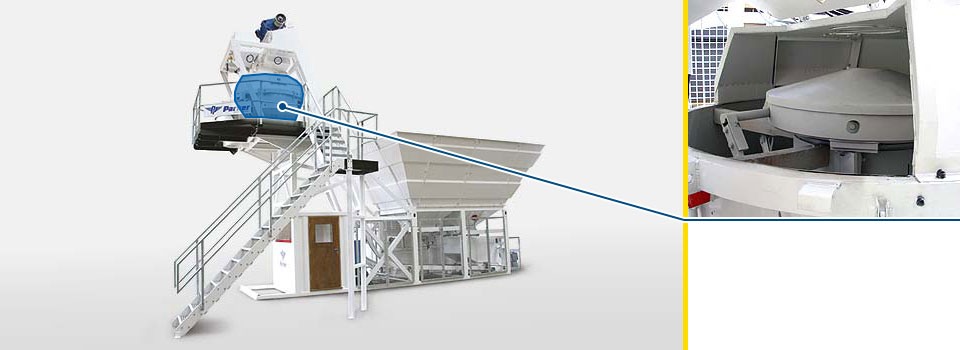

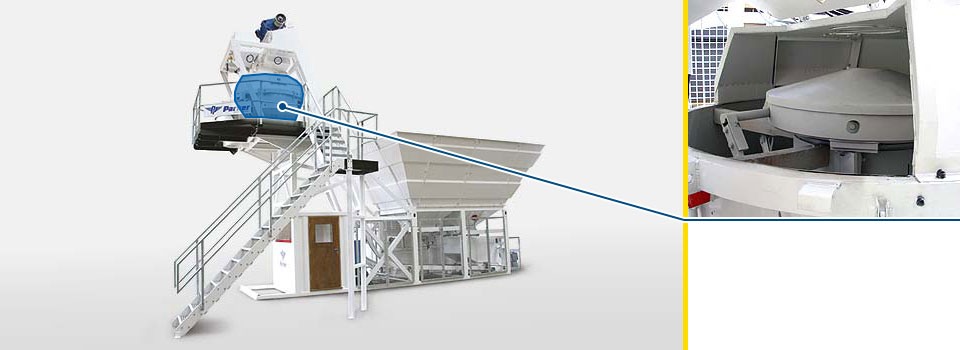

Pan Mixer

Features hard wearing abrasive resistant liner plates, paddle arms and tips. The arms are spring loaded and adjustable to compensate for wear and the paddle tips can be adjusted to increase or decrease the angle. Dry mix and twin shaft mixer options.

-

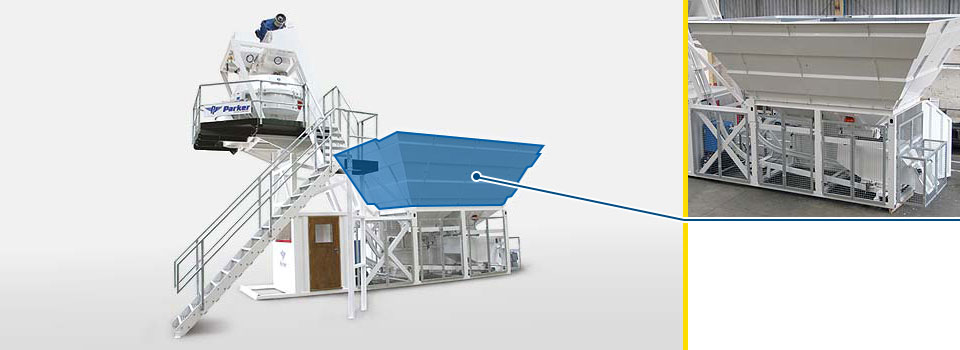

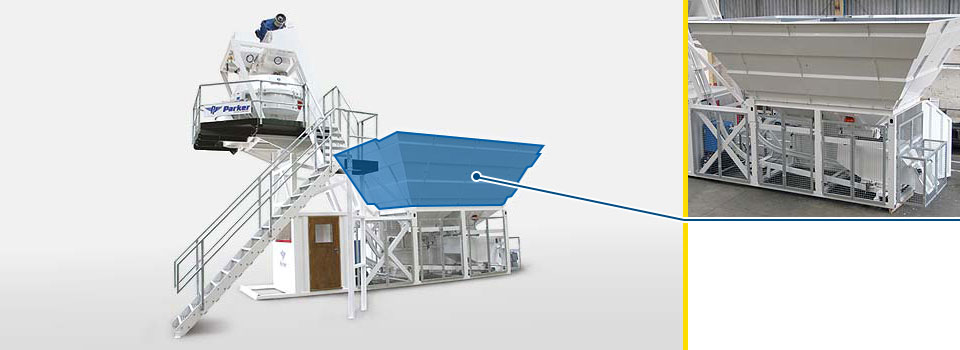

Feed Hopper

Has four compartments for different aggregate sizes, each holding 7.5m³ of material with bolted hopper extensions which are removed for transport. Vibrators are mounted on two of the hoppers to prevent build up of fine material.

-

Aggregate Weigh Skip

Aggregates are weighed within the skip and transported to the mixer via an inclined skip track. This method eliminates the need for a weigh conveyor and results in less wear at the discharge points and greatly reduces potential spillage areas.

-

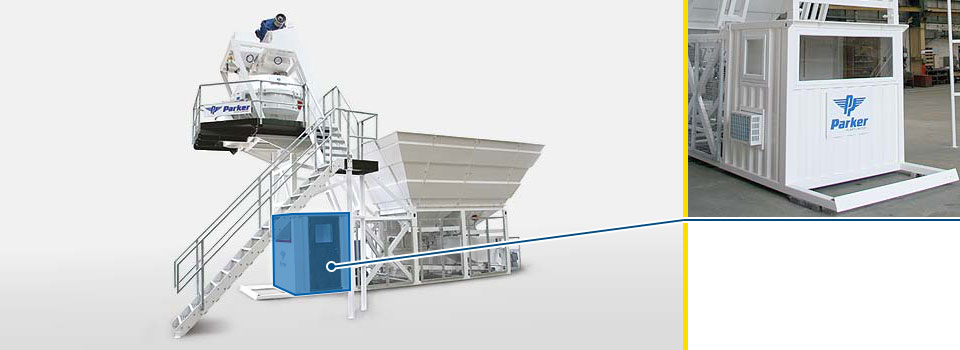

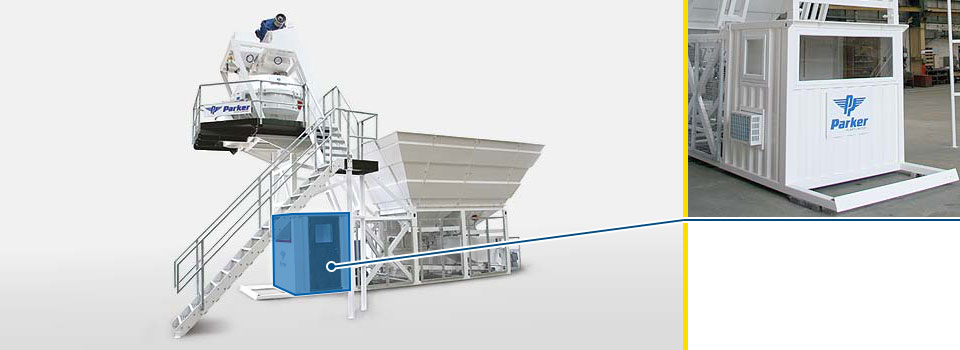

Control Cabin

The control cabin is pre-wired and fully tested prior to despatch. The Constar PLC based control system gives fast, accurate measurement of mix ingredients, as well as monitoring dynamic aspects of the plant for continuous and safe operation.

-

Access & Walkways

The extensive access & maintenance platforms are provided to mixer level are easily removed for transportation.

- Main structure can be transported in a 12m (40ft) open top container

- Installed and operational within 4 hours

- 2 speed skip to reduce cycle time

- Unique skip weigh system- no weigh conveyor required

- Factory pre-wired and fully tested

- Fully automatic control system

- Multi recipe for all concrete specs

| Specification |

| |

Units |

|

| Capacity |

| Output Capacity |

m³ / h |

30 |

| Aggregate Hopper |

| Compartments |

- |

4 / 2 |

| Compartment Capacity |

m³ |

4 x 7.5 |

| Total Feed Capacity |

m³ |

30 |

| Loading Width |

m |

3 |

| Loading Height |

m |

4.2 |

| Hopper Vibration Power |

kW |

2 x 0.18 |

| Aggregate Weigh Skip |

| Weighing Capacity |

L |

750 |

| Number of Load Cells |

- |

4 |

| Skip Winch Drive |

kW |

9.5 |

| Cement Weigh Hopper |

| Capacity |

kg |

300 |

| Pneumatic Vibration |

- |

YES |

| Water Weigh Hopper |

| Capacity |

kg |

200 |

| Additive Weigh Hopper |

| Capacity |

kg |

20 |

| Pan Mixer |

| Dry Capacity |

L |

750 |

| Compacted Concrete Capacity |

L |

500 |

| Mixer Drive |

kW |

22 |

| Compressor |

| Compressor Power |

kW |

5.5 |

| Pressure |

bar |

6.5 |

| Control Cabin |

| Dimensions |

m |

2.1 x 1.7 |

| Transport Dimensions |

| |

Units |

|

| Length |

mm |

11,500 |

| Width |

mm |

2,100 |

| Height |

mm |

2,270 |

English (UK)

English (UK)  Русский (RU)

Русский (RU)